What Is A Plaster Model Scanned In Order To Create An Exact Digital 3d Model Of Gold-Plated Coins Or Medals?

This involves scanning a plaster maquette to create a 3D digital representation of gold medals or coins. Specialized equipment is used to record the specifics and dimensions of the physical model into a digital version. This digital replica is used in a variety of ways throughout the production.

3D Scanning: High-resolution 3D scanners are employed to capture all details and dimensions of the model. These scanners employ various methods to take precise measurements.

Capturing Surface Data - The scanner emits light or laser beams that hit the surface of a model. The scanner captures these reflections and distortions. This data is used to create an accurate model.

Data Collection- As it moves along the surface of the models made of plaster, the scanner gathers an enormous amount of data points. These data points are then used to create an electronic model of the model that includes its geometry, contours details, and contours.

Conversion to 3D Model. Specialized software transforms information gathered from data into a 3D representation. This model mimics the physical dimensions and characteristics of the maquette.

What are the reasons for making a digital 3D model?

Precision and Replication- Digital 3D models enable precise reproduction of the model's specifications and dimensions. This will ensure that the final gold coins and medals are created to be in line with the intended design.

Digital models are easily modified and refined. Designers are able to alter the 3D model, but not alter the original maquette.

Compatible with Manufacturing ProcessesCompatibility with Manufacturing Processes Digital 3D models are compatible with different manufacturing processes, such as 3D printing or CNC machine and enables the creation of molds or dies for mass production.

Digital 3D model archives and documentation- Digital models are archived as records of the design. Digitally stored 3D models may be used for future references, reproductions or for historical documentation.

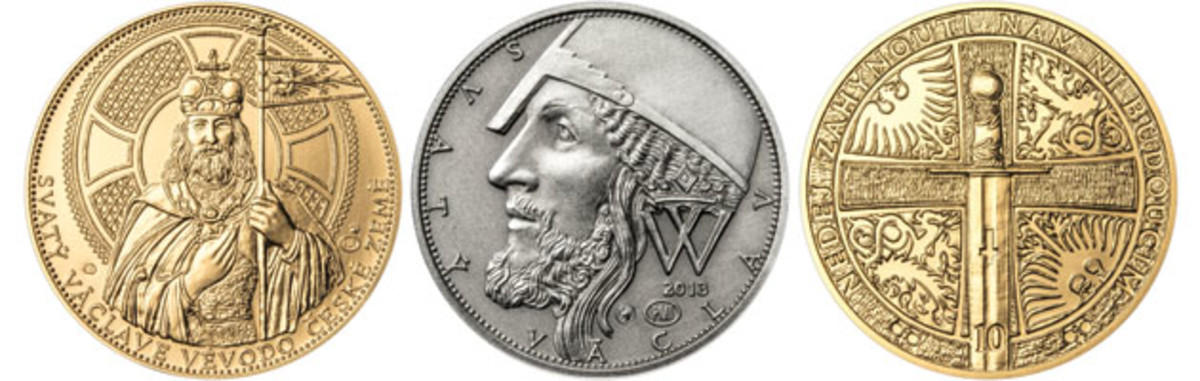

Designers and manufacturers can employ modern manufacturing techniques to make gold coins and medals that are precise and true to the original design. This is done by scanning the plaster models and creating digital 3D models. Have a look at the most popular Scanning and 3D Modeling Prague Mint gold coins more tips. including old silver coin, 2000 olympic, silver price jm bullion, st gaudens double eagle, gold doubloons, gold bullion bars, 50 dollar gold piece, coin 1, gold bars for sale near me, gold piece price and more.

What Are The Reasons Why The Dies Used Strike Gold Coins And Medals Undergo Processes Of Hardening By Vacuum?

The vacuum hardening of dies that are used to make gold medals and coins is accomplished by exposing them to high temperatures under controlled conditions in a chamber. Here's a quick guide on how to vacuum harden dies.

It is essential that the dies used to strike medals and coins are completely clean, free of dirt and other contaminants.

Loading in Vacuum Furnace

The dies are placed inside the vacuum furnace, which is a specialized chamber for heat treatment that is capable of creating an atmosphere of vacuum.

Evacuation of Aircraft

Vacuum furnaces remove air from chambers, resulting in an oxygen-free atmosphere. This prevents oxidation and ensures the same heat treatment.

Heating Phase

The furnace is heated to a certain temperature to solidify the dies. The temperature is determined by the material being used and the method by which it will be cured.

Soaking at high temperatures-

Die dies are kept at a high temperature for a specific time which allows the material to achieve and keep the desired hardness and metallurgical structure.

Cooling and Quenching

Following the soaking phase, the dies can be quickly cooled with the help of specialized techniques. The speedy cooling allows the metal to achieve the required hardness.

Tempering (Optional)The Tempering Process (Optional)

In certain cases, a tempering process follows the process of hardening. Tempering is the process of heating dies to a lower temperature, which helps alleviate internal stress and increase toughness while maintaining their hardness.

Quality Control and Inspection

Dies with hardened material must undergo rigorous quality control and inspections to attain the desired hardness, strength or dimensional tolerances.

Post-Treatment Handling-

When the process of hardening by vacuum is completed Die dies are then subject to further processes like polishing or coating prior to being utilized for the coin or medal striking process.

The process of hardening by vacuum increases the wear resistance, durability and longevity of dies used to make gold coins or medals. This procedure, which creates an atmosphere free of airborne contaminants, ensures that dies are consistently hardened and consistently, enhancing both the quality and durability of the products. Have a look at the most popular vacuum hardening Czechoslovakia gold medals blog examples including buy gold silver, silver price in dollar, silver price in dollar, american eagle gold coin 1 oz, 1 0z gold, buy gold silver, st gaudens gold coin, bullion price of silver, 5 dollar gold coin, 1 4 ounce gold coin and more.

How Do Gold Medals And Coins Receive Their Protective Coatings?

Coating gold medals or coins is done for a variety of reasons. This includes protection, improving the appearance or creating a certain aesthetic look. Below are some of the different coatings that can be applied.

Clear Protective Coating (Varies)Clear protective coating, such as lacquer or a specially-formulated polymer, may be applied to protect the surface against the effects of tarnishing, oxidation or scratches. The coating will preserve the original appearance of the coin or medal and shields the base metal.

Enhancement of Appearance

Gold plating or Gilding - A thin layer of gold is applied to gold medals or coins. This results in a medal or coin having a a more luxurious, lustrous finish.

Aesthetic Effects

Antique finishes and patinas can be made by chemical treatments, or coatings. This creates a aged or oxidized appearance on the surface. It gives character and depth to your design.

Coloring or Colorization - Certain metals or coins are colored in specific areas with the help of coatings, enamels or other specialized coatings. The colors are utilized to emphasize certain design elements or to make a contrast.

Anti-Tarnish Coatings-

Anti-Tarnish Solution: If the medal or coin is intricately designed, or has specific areas are prone to tarnishing you may want to apply anti-tarnish products. The coatings can stop metal surfaces from becoming discolored or oxidized with time.

Specialized Coatings that Ensure Security or Authentication

UV-Reactive Coatings. Certain coins or medals may have coatings, which react with UV light and reveal hidden or encrypted elements. They are utilized for security and authentication purposes.

Selective Coatings to Enhance Contrast

Selective Coating Removal- In certain cases the coatings on coins or medals are removed in a selective manner to create contrast when polished and coated surfaces.

Each coating procedure is created to achieve a particular purpose. This might be to improve aesthetic or security features, or even protect the metal. The coatings can affect the visual appeal, durability and value of gold coins and other kinds of medals. Follow the top rated coating Prague Mint gold coins website examples. including 100 grams gold biscuit, order gold coins, gold and silver bullion, 24k gold bullion, platinum coins, gold silver dealers, gold silver coins, sacagawea gold dollar, silver eagle coins, gold coin gold and more.

What Is The Process For Having Gold Coins And Medals Checked For Quality To Ensure Compliance With Specifications?

These checks are performed to make sure that the coins or medals meet specifications and that they have a precise surface. These checks are made up of various stages.

The inspectors inspect the medal or coin visually for surface flaws or imperfections, as well as blemishes. They search for marks, scratches or marks that may affect a coin's value or appearance.

Dimensions and weight

The process of weighing and weighing each medal or coin will ensure that it satisfies the specified weights and diameters, thicknesses, and overall dimensions as per the design specifications. Any deviations could be a sign of an issue with the product.

Metal Purity and Composition

Using X-ray Fluorescence (XRF) as well as chemical analysis, or any other testing methods to verify the purity and gold content of the coins or medals. This ensures that the medals and coins conform to the standards required for gold content.

Edge InspectionEdge Inspection

Inspectors inspect the edges of coins and medals to check for uniformity, anomalies (if they are present) and reeding. The edges are an important place to add security features or other design elements.

Strike Quality-

To assure consistency To ensure uniformity, the quality of the strike is assessed to determine the sharpness, clarity and the relief of design elements and the overall appearance.

Proofing and Minting errors-

Proof coins and special editions are inspected with a careful inspection in order to detect any imperfections, mistakes or discrepancies that could impact their collectible value.

Packaging and Packaging and

Packaging and presentation are subject to quality checks. This ensures that coins and medals are stored correctly, or displayed in cases or holders, free of damage or contamination.

Sampling and Random Checks-

Random checks or random sampling are performed on each batch to ensure that the highest quality standards are maintained throughout the entire minting process.

Documentation and Compliance-

Every quality check must be documented in order to be in compliance with all laws as well as certification requirements and minting standards. These records are proof of authenticity and quality.

Rejection of Pieces that aren't Conforming

Rejecting medals or coins that do not meet the standards of quality is a great way to ensure the integrity and quality of the product.

Through these rigorous quality checks, mints can ensure that gold coin or medals are in compliance with the standards required, which include purity, accuracy of appearance and value. They reassure collectors as well as investors and consumers. View the recommended Czechoslovakia gold medal quality control more examples. including gold biscuit buy, gold price coin today, 1 oz gold, gold bullion, $5 gold coin, mexican gold coins, coin gold price today, 1 oz gold coin price today, 1975 gold penny, gold silver shops near me and more.

Comments on “Recommended Ideas For Numbering Prague Mint Medals”